HMI SCADA Software

HSQ Technology’s MISER HMI SCADA software is highly configurable and secure platform with exceptional features for SCADA telemetry systems. Customers around the globe trust their operations to MISER. The current VMS version will be supplemented in 2023 with a Windows version powered by Nucleus Command Systems.

HSQ Technology’s MISER HMI SCADA software is highly configurable and secure platform with exceptional features for SCADA telemetry systems. Customers around the globe trust their operations to MISER. The current VMS version will be supplemented in 2023 with a Windows version powered by Nucleus Command Systems.

- Distributed, real-time databases (unrestricted licensing up to 64,000 points)

- True client-server architecture

- X-Window/Motif graphical user interface (Xview)

- Buffered RTU data with time-stamping means no data loss in the event of communication outages. Data is be stored and backfilled once communications are recovered, retaining the original time-stamp of when the event actually occurred.

- History data recording and trending

- TCP/IP open network communications

- MISERnet – high performance report by exception database linking

- Multiple open hardware and software platform support

- Redundant server with automatic fail over

- Redundant data highway (LAN) and remote communications

- Remote user access via Windows-based computer.

- Supports ORACLE and SQL relational history databases

- Data export to MS Office and other PC applications

- VisualCL – HSQ’s IEC 61131-3 graphical function block language

- Browser access to on-line manuals

MISER includes historical data recording, retrieval, and spreadsheet style reporting functions. MISER report by exception-based history recording all data changes. Each change is recorded with a time-stamp indicating the time the change was detected by the RTU. Report by exception-based history is saved to daily record files. An indefinite number of daily files that can be maintained online, depending on the frequency of reporting and the capacity of the online hard disk drive. Report by exception-based history is used to provide real-time history for recent history and to provide high resolution history over extended periods for selected points.

Both online and archived history functions are supported. Exception oriented recording and history compression utilities allow large history databases to be maintained online. Online history retrieval includes real time trend charting and historical trend charting. User configurable spreadsheet report files can be output in ASCII, DIF and XLS file formats to export data to popular PC applications.

At the core of MISER is MISERnet – a real time distributed database server engine. MISERnet servers distribute data to client nodes, which can be other servers or workstations. MISERnet also provides the master/host communications with distributed and remote RTUs or controllers. After receiving supervisory control commands from servers and workstations, it then communicates these to RTUs and controllers. MISERnet collects, stores and passes time-stamped report by exception data change events to the MISER historical database.

MISERnet is an application level, inter-node communications facility that utilizes standard TCP/IP or OSI data transport protocols. MISERnet operates over standard Local Area Networks (Ethernet and FDDI) or Wide Area Networks without conflict with other network applications. MISERnet is required only to support MISER Software and is not involved in communications between non-MISER applications.

To provide high system availability of the MISERnet server functions, a redundant pair of hot backup server is usually provided. The online server continuously updates the backup server with current data, and automatically fails over to the backup server should the primary server fail. Periodic wellness messages are passed between the primary and backup servers; failure to communicate initiates failover.

MISER supports a client/server architecture. XView performs display processing locally on the workstation, receiving only data from the MISER server engine. XView keeps slide display files resident on the workstation hard disk drive, so call up times are typically less than one second. Current real time data is saved by XView in a local copy of the MISER database, so slides come up with current data immediately. Once initialized, MISERnet updates the workstation database with data changes as they are processed by the server nodes. This client-server architecture, combined with the efficient report by exception data propagation methods used by MISERnet, maximizes overall network efficiency.

MISER does not have separate development and run time versions. MISER workstations are provided with all development tools, including both XView and XDraw. These tools support on-line operations and provide the properly privileged user with access to the slide, database and control logic development tools needed to build, maintain and enhance the system configuration. MISERnet automatically distributes system configuration changes to all workstations, eliminating the need to manually update these changes

The MISER Host server software runs on high performance Itanium RISC-based real-time platforms. MISER workstations run the HSQ XView graphical user interface (GUI) software, an X-Window/Motif operator interface. XView is available on Itanium RISC workstations running OpenVMS or Windows, and on Intel-based PCs with Windows. XView provides object oriented graphic slide windows for users to view data and execute supervisory control actions. XView stations include XDraw, an integral graphics development application.

MISER includes historical data recording, retrieval, and spreadsheet style reporting functions. MISER report by exception-based history recording accumulates data change events, including both digital and analog values. Each change is recorded with a time stamp, current value, historical data, alarm status, and the point quality status.

Both online and archived history functions are supported. Exception oriented recording and history compression utilities allow large history databases to be maintained online. Online history retrieval includes real-time trend mapping and recovery.

Optional Relational Database Management System (RDBMS) tools are used to provide powerful and flexible relational database facilities for point configuration data and history data management, as well as various data export interfaces, including SQL, ODBC, and DDE for interaction with Wonderware Historian, Microsoft SQL Server, GE Historian, Oracle MySQL, OSI PI, and more. Developer tools can also be provided for reports and RDBMS application development.

MISER supports RTU/controller communications, also known as Network Communication Controllers (NCCs) for use over all media typically used in the industrial applications including analog and digital leased lines, cellular modems, and radios.

The supported communications protocols include:

- HSQ’s extremely efficient report by exception communications protocol, with buffered data and time-stamping, means no data loss in the event of communications failure. All data will be recorded and backfilled once communications are restored, retaining the original time stamp of when the event actually occurred.

- ENCIP

- Allen Bradley DF1 Master

- Modbus RTU (Slave and Master)

- Modbus TCP/IP

An IEC 61131-2 compliant graphical function block language for implementation of calculations and control logic, the program is designed to operate on MISER real time databases. VisualCL programs run on any MISER server or workstations, and on Model 25×86 Logic Processors. Algorithms can be developed on any MISER workstation with the VisualCL editor, and can then be downloaded via the system network to the execution node. Includes graphical editor, code compiler and online debugger.

Logic Processors

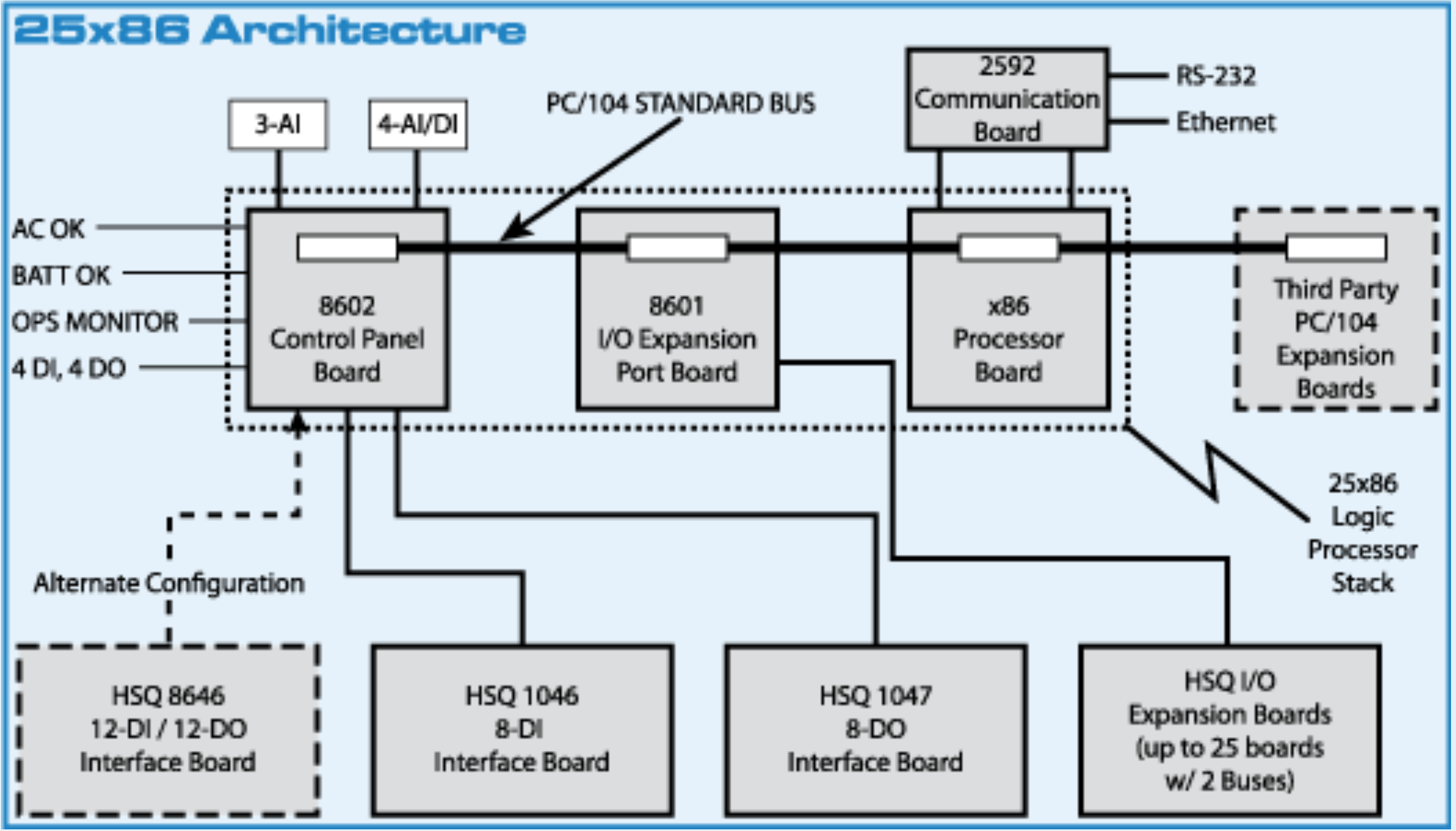

The Model 25×86 Logic Processor Stack is an x86-based data acquisition and control computer intended for a wide range of telemetry, SCADA, distributed automation and facilities management applications. The 25×86 processor board provides software and communications compatibility with existing HSQ Model 2500/86 and HSQ Model 2500 Processors.

The Model 25×86 Logic Processor Stack is an x86-based data acquisition and control computer intended for a wide range of telemetry, SCADA, distributed automation and facilities management applications. The 25×86 processor board provides software and communications compatibility with existing HSQ Model 2500/86 and HSQ Model 2500 Processors.

The Model 25xX86 is provided with HSQ developed

software which supports report-by-exception, real-time clock synchronized to the master system clock, local time-stamped Sequence of Events (SOE), local alarm detection and engineering units conversion, and user

definable computations and control logic.

- Industrial x86 Processor

- Open PC/104 Bus Architecture

- HSQ Model 2500/86 Compatibility

- Distributed Alarm and Data Processing

- Sequence of Events (SOE) Buffering

- Synchronized Real Time Clock

- Intelligent Stand Alone Control

- VisualCL Programming (IEC 1131-3 Based)

- Scalable I/O Battery

- Backup Power Supply Option

- Redundant Power Supply Option

- Redundant Processor Option

- IEEE 802.3 10/100Base-T Ethernet

- IP LAN/WAN Support

- Modbus Master and Slave Capability

Processor Boards

Processor Type: | x86 1.0 GHz (Standard/Low Power) |

|---|---|

Memory: | 256 MB SDRAM, expandable |

Non-Volatile Memory: | 64 MB CompactFlash standard, expandable |

Real Time Clock: | Year, Month, Day, Hour, Minute, Seconds and an On-Board Clock Battery |

Watchdog Timer: | Automatic System Reset after Software Failure |

Ethernet Interface: | Embedded 10/100MB (UDP and TCP/IP) |

Serial Ports: | Three RS-232 and One RS-232/485 standard, expandable, USB available |

Master Protocol: | Allen Bradley DF1, Modbus Master (Serial/TCP), DNP3 |

Remote Protocol: | HSQ COS Protocol, Modbus Slave (Serial/TCP), DNP3 Slave |

PC/104 Connector: | Allows access to Open PC/104 Bus Architecture (32-bit) |

HSQ 8602 Control Panel Board

Indicators: | Power, Stand Alone Active, Outputs Enabled, Initialized by Host, Door Open |

|---|---|

Switches: | Stand Alone Mode (Forced/Auto/Inhibit), Outputs Enable/Disable |

Embedded I/O: | 12 TTL Digital Inputs, 12 TTL Digital Outputs |

| 4 Analog Inputs, (4-20mA, 0-1mA, 0-5V, 0-10V) (Note: Configurable as 24VDC Digital Inputs) | |

| 3 Analog Inputs (4-20mA) | |

| Auxiliary I/O Port: 4 TTL Digital Input and 4 TTL Digital Output | |

I/O Expansion Bus Port: | 2500 Series I/O Expansion Boards, up to 25 boards, 832 points |

Battery Voltage Monitor: | On-Board AI Monitors +24VDC Supply Voltage, Reads Battery Volts During Discharge |

AC OK Monitor: | TTL from 2585 Power Control Board, Indicates AC Power Being Used, i.e., Battery Not Discharging |

Battery OK Monitor: | TTL from 2585 Power Control Board, Indicates Defective Battery |

Address Switches | Unit Address, 1-999 |

Ops Monitor Relay | 24 VDC, 10 A Maximum |

Door Alarm | Photocell Activates Internal Alarm Point When Illuminated, Adjustable Threshold |

General

Logic Power | 5 VDC, 6 W (Standard) 3.7-4.4 W (Low Power) |

|---|---|

Field I/O Power | 24 VDC, Power Consumption Varies by I/O Configuration |

Temperature | 0-60°C Operating |

| (Optional Thermostatically Controlled Heater for Extended Low Temperature) | |

Humidity | 5-95 Percent Relative Humidity, Non-Condensing |

Dimension | 17.78 cm x 25.40 cm (7″ H x 10″ W) – Depth Varies According to Board Configuration |

DIN Rail Mounting: | Fits standard DIN rails (35 mm) |

HSQ AUX I/O Interface Boards

|

|

2500 Series I/O Expansion Boards

|

|

HSQ 6000/6200 Series Remote I/O Modules

|

|

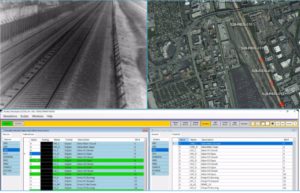

Long-Range Intrusion Detection System

HSQ Technology’s Long-Range Intrusion Detection System is built to go the distance. Unlike most systems, its engineered to monitor wide-expanses of territory, integrating cameras and sensors into a unified operations platform.

HSQ Technology’s Long-Range Intrusion Detection System is built to go the distance. Unlike most systems, its engineered to monitor wide-expanses of territory, integrating cameras and sensors into a unified operations platform.

With decades of experience designing and implementing remote telemetry systems, HSQ Technology’s intrusion detection system is a sophisticated solution that’s easy to install, simple to operate and highly secure. It’s perfect for monitoring long-range assets such as pipelines, railways, guideways, military bases, and borders.

Key Features:

- Industrial x86 Processor

- Open PC/104 Bus Architecture

- HSQ Model 2500/86 Compatibility

- Distributed Alarm and Data Processing

- Sequence of Events (SOE) Buffering

- Synchronized Real Time Clock

- Intelligent Stand Alone Control

- VisualCL Programming (IEC 1131-3 Based)

- Scalable I/O Battery

- Backup Power Supply Option

- Redundant Power Supply Option

- Redundant Processor Option

- IEEE 802.3 10/100Base-T Ethernet

- IP LAN/WAN Support

- Modbus Master and Slave Capability

HSQ Technology’s Long-Range Intrusion Detection System is a control system designed and developed to provide 24/7 monitoring of right-of-way safety. It incorporates physical sensors and cameras with state-of-the-art software for a higher level of security and safety. Previously, guideways were completely dependent on operators to detect and react to impediments.

At the heart of HSQ Technology’s Long-Range Intrusion Detection system is the HSQ Gateway server. It processes tilt sensor and video events and sends event notifications to both operators monitoring workstations and to automatic train control systems in the case of an emergency. And through the use of georeferencing, it can pinpoint the exact position where an event is detected.  The cameras and sensors provide data that is instrumental in determining the level of an event: Low-Level Events (LLEs) and High-Level Events (HLEs). LLEs can be triggered by a variety of factors, including the deflection threshold being exceeded, a loss of communication (with a sensor or camera), or a small object entering the monitored area. LLEs are only shown to operators and not sent to the ATC system. HLEs are triggered by more serious events, including a severe deflection, a communication failure of more than two sensors per zone, or a Video Analytic detection of an intrusion. HSQ Technology’s Long-Range Intrusion Detection System interacts with existing Automatic Train Control systems to send ‘zero’ speed signals to trains when there is hazard on the tracks. This allows trains to be stopped without human intervention when an emergency occurs.

The cameras and sensors provide data that is instrumental in determining the level of an event: Low-Level Events (LLEs) and High-Level Events (HLEs). LLEs can be triggered by a variety of factors, including the deflection threshold being exceeded, a loss of communication (with a sensor or camera), or a small object entering the monitored area. LLEs are only shown to operators and not sent to the ATC system. HLEs are triggered by more serious events, including a severe deflection, a communication failure of more than two sensors per zone, or a Video Analytic detection of an intrusion. HSQ Technology’s Long-Range Intrusion Detection System interacts with existing Automatic Train Control systems to send ‘zero’ speed signals to trains when there is hazard on the tracks. This allows trains to be stopped without human intervention when an emergency occurs.

Cameras:

Infrared intrusion-detecting cameras are placed on poles that provide an unimpeded view of the track right-of-way and to make them less vulnerable to sabotage and theft. Cameras are placed at intervals and directions so that there are no blind areas and there are overlapping fields of view. By using infrared cameras, imaging is available anytime of the day or night and is also unaffected by fog, rain, snow, or other weather circumstances. The cameras are capable of determining an intrusion as small as one cubic foot or adjusted larger in order to limit false alarms all while providing notification of an encroachment likely to cause harm.

Sensors:

Tilt sensors are placed on fence posts that delineate the right-of-way from the surrounding areas. They detect any event that causes the post to deflect beyond the preset minimum threshold angle but are unaffected by mere strikes against the fence. Tilt sensors collect fence tilt level information and send it to the HSQ Gateway for processing. A serial server converts the Modbus serial protocol data from the tilt sensors using the Modbus TCP protocol before sending it to the HSQ Gateway. The sensors ‘X’ and ‘Y’ positions are polled continuously by the HSQ Gateway server. For any sensor tilt angle feedback that exceeds the minimum limits set for that sensor, a low or high level event is generated and is shown as a zone-wide event on the operator workstation.

Servers and Software:

HSQ Technology’s Intrusion Detection System logic uses two sources of information in order to make determinations for activating event levels for intrusions into the rail right-of-way track area. The fence-mounted tilt sensors comprise one source and the zone thermal imaging-based video analytics comprises the second source. The HSQ Gateway is where the logic to resolve this event level determination occurs. The Video Analytics server houses the video portion of RIDS. Video streams from the thermal imaging cameras are analyzed for detection of objects based on predetermined criteria. If an event is detected, the server communicates the detection information to the Gateway server and then sends video and event logging data to the operator workstation.

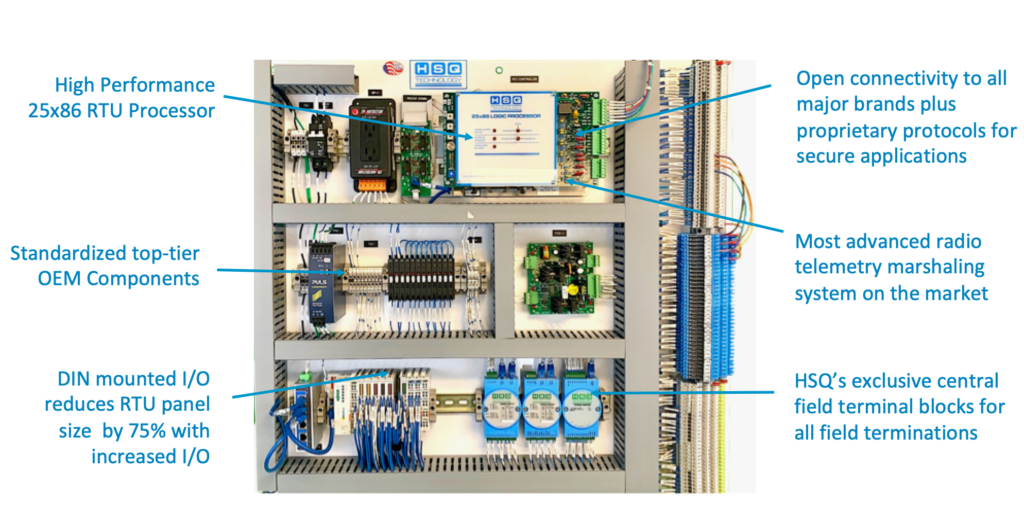

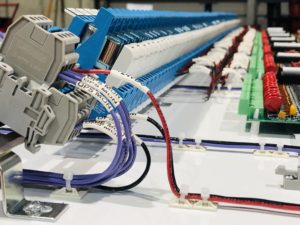

UL Certified Control Panels

HSQ control panels are handcrafted in the U.S.A. using high-grade components and quality control techniques. Every wire is labeled, ever termination is precisely torqued, and every connection is thoroughly tested before it leaves our factory.

HSQ Technology takes great pride handcrafting control panels that are built to perform for decades. We use top-tier components in our standard designs that have proven themselves in the field and assemble them in a cabinet that is easy to install and simple to maintain.

HSQ Technology takes great pride handcrafting control panels that are built to perform for decades. We use top-tier components in our standard designs that have proven themselves in the field and assemble them in a cabinet that is easy to install and simple to maintain.

Each panel that leaves our factory is custom built to customer requirements and environmental conditions. Whether it’s a small indoor enclosure or a freestanding stainless steel outdoor one, the build quality and to attention to detail remains the same.

HSQ Technology takes great pride in documenting everything we do so that we’re able to support every panel that leaves our shop remotely. After decades of perfecting the art of integration, our fabricated RTU and control panels are second to none.

|

|

Features:

- Custom panel design, fabrication, and wiring

- Hot-dipped galvanized steel, aluminum, or stainless steel construction

- Maintenance-friendly designs that are built to last decades

- Integrated UPS, battery, or generator power back-up options

- Sunshields, heating, and air conditioning accessories are optional

- UL 508A label if required